Industrial SU Form

The SU Type coupling has a single flex plane with two hubs as well as a single disc pack. It truly is ideal for angular and axial misalignment only. Two SU couplings are often mixed using a shaft

to generate a floating shaft coupling. The shaft may be hollow for lengthy light fat floating shaft couplings.

Industrial SX Style

This is certainly the regular coupling kind that consists of two hubs, a stock length spacer developed to meet business standard lengths, and two unitized disc packs. The coupling has two flex planes, one particular at each disc pack, enabling this coupling to accommodate parallel, angular, and axial misalignment with specified limits. The coupling is available in six and 8 bolt styles and bore sizes up to 13 inches (330mm) on the biggest size. Customized spacer lengths could be manufactured to meet special shaft separations essential for certain applications. The SX coupling can be fitted with overload bushings to guard the disc packs in above torque circumstances and may act as an anti-flail device. SX couplings are assembled with the time of installation to the products exactly where the coupling are going to be in service.

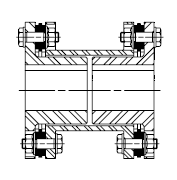

Industrial DI Style

The DI Type coupling features a “Drop-In” spacer assembly that’s assembled in the factory. The coupling consists of two hubs as well as a spacer assembly comprising in the spacer, two unitized disc packs, and two guard rings. The disc packs are bolted to your spacer and guard rings in the factory working with the torque values proposed by Lovejoy for that disc pack bolts. With the hubs mounted on the shafts, the whole disc pack assembly is often “Dropped In” area between the two hubs. The hubs are piloted to ensure suitable centering of your spacer assembly. This piloting serves as an anti-flail function and aids from the coupling’s ability to meet the stability specifications mandated by API. This fashion coupling is made to meet the stability and anti-flail demands specified in API-610.

Oversized, or Jumbo, hubs can be found for use using the DI Kind coupling to allow for more substantial bore sizes  on most DI coupling sizes. This allows for the use of smaller sized DI couplings in applications in which a smaller dimension coupling can still accommodate the application torque.

on most DI coupling sizes. This allows for the use of smaller sized DI couplings in applications in which a smaller dimension coupling can still accommodate the application torque.

Industrial SXC Type

The SXC Form may be the near coupled variation of your SX Sort coupling. The SXC is much like the SX coupling in the disc packs are connected when the coupling is set up. Inside the close coupled units, the hubs are turned inward and therefore are mounted inside the spacer. Note that with the hubs within the spacer, the maximum bore permitted within the hub will likely be decreased. The SXC couplings is usually employed with a single or each hubs turned outward to permit the coupling to accommodate unique shaft separations.

Industrial SXCS and SXCST Kinds

The SXCS and SXCST Sorts have split spacers and the disc packs is usually serviced or eliminated without moving the hubs within the shafts and devoid of moving the equipment. The SXCS Style has the bolts that connect the hubs to the split spacer set up in the ends of your couplings. The SXCST have the bolts set up from inside the spacer pointing outward towards the hubs.

Extra Types